| The fully-electric machine concept from Sumitomo (SHI) Demag is based on innovative direct drive technology. Direct drive machines offer increased energy efficiency while their greater responsiveness ensures that they can achieve higher levels of precision, improved repeatability and shorter turnaround times than indirect electric drives. That means our electric machines are best equipped to solve the challenges faced by manufacturers of mass-produced precision parts.

The increased efficiency delivered by direct drives means that they use considerably less energy than hydraulic machines – in the case of the IntElect between 40% and 85% less than conventional solutions. And because electric drives generate less heat than their hydraulic counterparts, they require less cooling than conventional machines of a similar size, thus reducing the burden on your electrical infrastructure and the investment required when building new premises.

The IntElect is available in two versions: smart and performance. Both feature fully-electric direct drive engines generating up to 220t of clamping force to drive the main axles of the clamping unit and the injection unit. Both versions also have an extensive catalogue of options and a standardised modular automation solution.

Ultimately it’s the result that counts …

…so it’s important to have a reliable partner at your side. And the IntElect represents the ideal partner, combining all the experience gained in the completion of over 30,000 electric machine installations worldwide.

Whether your business is automotive engineering, electronic engineering, clean-room medical technology, packaging or micro-technology, the IntElect is the ideal machine whenever the situation demands repeatable production of precision-moulded parts.

Electronics – fast and efficient: fluorescent tube holder

Packaging – accurate, repeatable with reduced wear on moulds: spray head

Clean-room medical technology – safe and economical: inhaler

Automotive – error-free just-in-time delivery: connector

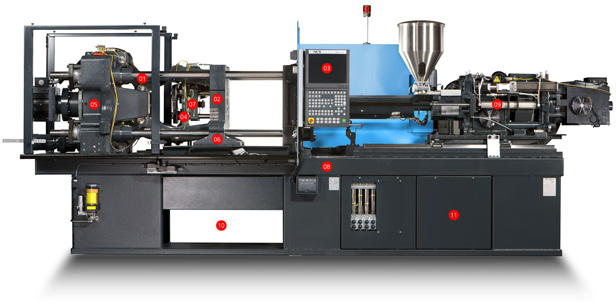

IntElect Smart

The smart version combines a drive technology specifically designed to support injection moulding processes with solid German engineering delivered by our manufacturing facility in Thüringen. The result is a high-precision, dynamic, resource-efficient injection moulding machine that represents excellent value for money.

- 5-point dual-toggle leverwith optimum kinematics and computer-optimised braking and acceleration profiles delivering the highest levels of precision and energy efficiency

- High platen parallelismachieving the highest levels of precision with minimum wear and tear on moulds

- Intuitive NC5 controlfeaturing a process-oriented user interface for easy adjustment, monitoring and documentation

- Active mould protectionusing a high-resolution measurement system with piezoelectric sensors and fast signal processing facilitated by the high clock-frequency of the control unit

- Dynamic and precise clamping unitfeaturing active energy-recovery technology

- Guide system for the movable clamping plate

allowing uninterrupted linear guidance, the highest levels of precision and heavier mould weights

- Rapid ejectordelivering the shortest possible reaction and response times, available as a belt-driven ejector in the smart version

- Compact and robust machine bedfor the highest levels of precision, minimal wear on moulds and excellent durability

- High-performance injection unitfor the highest levels of precision, fast dosage and injections. The constant L/D ratio (20:1) ensures increased melt homogeneity for even the most difficult colourings. Automatic cylinder detection facilitates fast turnaround times and flexible retooling for different product runs.

- Wide delivery shaft, open on three sidesfor a flexible flow of materials and easy integration of peripheral components

- Free spaceallowing integration of a hydraulic module into the machine bed for machines of up 160t clamping force. Can be used for several machines.

Smart Version

- A fast standard injection speed of 300 mm/s up to 210t continuous clamping force

- Air-cooled direct drives capable of generating up to 220t of continuous clamping force for the core axles for plasticising, injection and opening the mould

- Servohydraulic nozzle unit combines the benefits of electrical control with the high load capacity provided by hydraulic systems

- Belt-driven ejector

- Air-cooled drives produced in our own factory at an attractive entry-level price

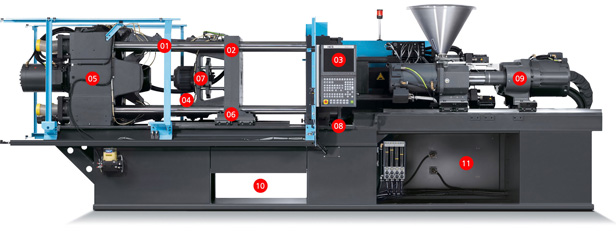

IntElect performance

The performance version uses water-cooled direct drives throughout and is the best solution for special clean-room environments.

- 5-point dual-toggle leverwith optimum kinematics and computer-optimised braking and acceleration profiles delivering the highest levels of precision and energy efficiency

- High platen parallelismachieving the highest levels of precision with minimal wear and tear on moulds

- Intuitive NC5 controlfeaturing a process-oriented user interface for easy adjustment, monitoring and documentation

- Active mould protectionusing a high-resolution measurement system with piezoelectric sensors and fast signal processing facilitated by the high clock-frequency of the control unit

- Dynamic and precise clamping unitfeaturing active energy-recovery technology

- Guide system for the movable clamping plate

allowing uninterrupted linear guidance, highest levels of precision and heavier mould weights

- Rapid ejectordelivering the shortest possible reaction and response times, available as a direct ejector in the performance version

- Compact and robust machine bedfor the highest levels of precision, minimal wear on moulds and excellent durability

- High-performance injection unitfor the highest levels of precision, fast dosage and injections. The constant L/D ratio (20:1) ensures increased melt homogeneity for even the most difficult colourings. Automatic cylinder detection facilitates fast turnaround times and flexible retooling for different product runs.

- Wide delivery shaft, open on three sidesfor a flexible flow of materials and easy integration of peripheral components

- Free spaceallowing integration of a low-noise hydraulic module. Can be used for several machines.

Performance Version

- Direct drives throughout:water-cooled direct drives for the core axles for plasticising, injection and opening the mould

nozzle unit with direct drives

dynamic direct ejector

- Short dry-cycle times for fast turnaround

- Guidance system fitted as standard

- Optimised for clean-room environments up to ISO class 7

- Up to 75% quieter than conventional machines

|